ELECTRICAL Design & Engineering

Quinea has extensive experience optimizing systems and processes using supervisory control and data acquisition (SCADA) systems and human machine interface (HMI) technologies for OEMs and End-Users; from operations management to the factory floor, we will work with you to determine your specific need, and design a custom solution that works for your organization. Intelligently designed Machine and Plant Control Interface and Data Acquisition are critical for intuitive, repeatable, and robust operations; our specialty is streamlining the operations environment to the individual organizational requirements using validated modular control concepts and components.

Whether an upgrade or new installation, we will help you design a SCADA/HMI system to better understand your process data and support more informed decisions; by employing batch management, historical data, and metric driven production planning you can improve your processes, maximize productivity, and minimize downtime.

- Assistance identifying operational issues

- Centralized real-time control

- Collection of critical process data

- Improved quality control

- Real-time and historical trending

- Batch and Recipe management for controlled and repeatable machine set-up

- Remote access with or without remote control capabilities

Our SCADA/HMI services can be turnkey or integral to your project team; from system planning and design, engineering, software development, programming, communication networks, control panels, implementation, commissioning to ongoing support.

Quinea has experience with a variety of different HMI and SCADA Systems but we excel with the vendors and products listed below:

HMI Products

- Siemens SIMATIC / TIA Panels

- Allen-Bradley PanelView

- GE QuickPanel / RXi displays

SCADA Software Schemes

- Siemens SIMATIC WinCC / TIA

- Rockwell FactoryTalk Package

- GE Digital Cimplicity / iFix

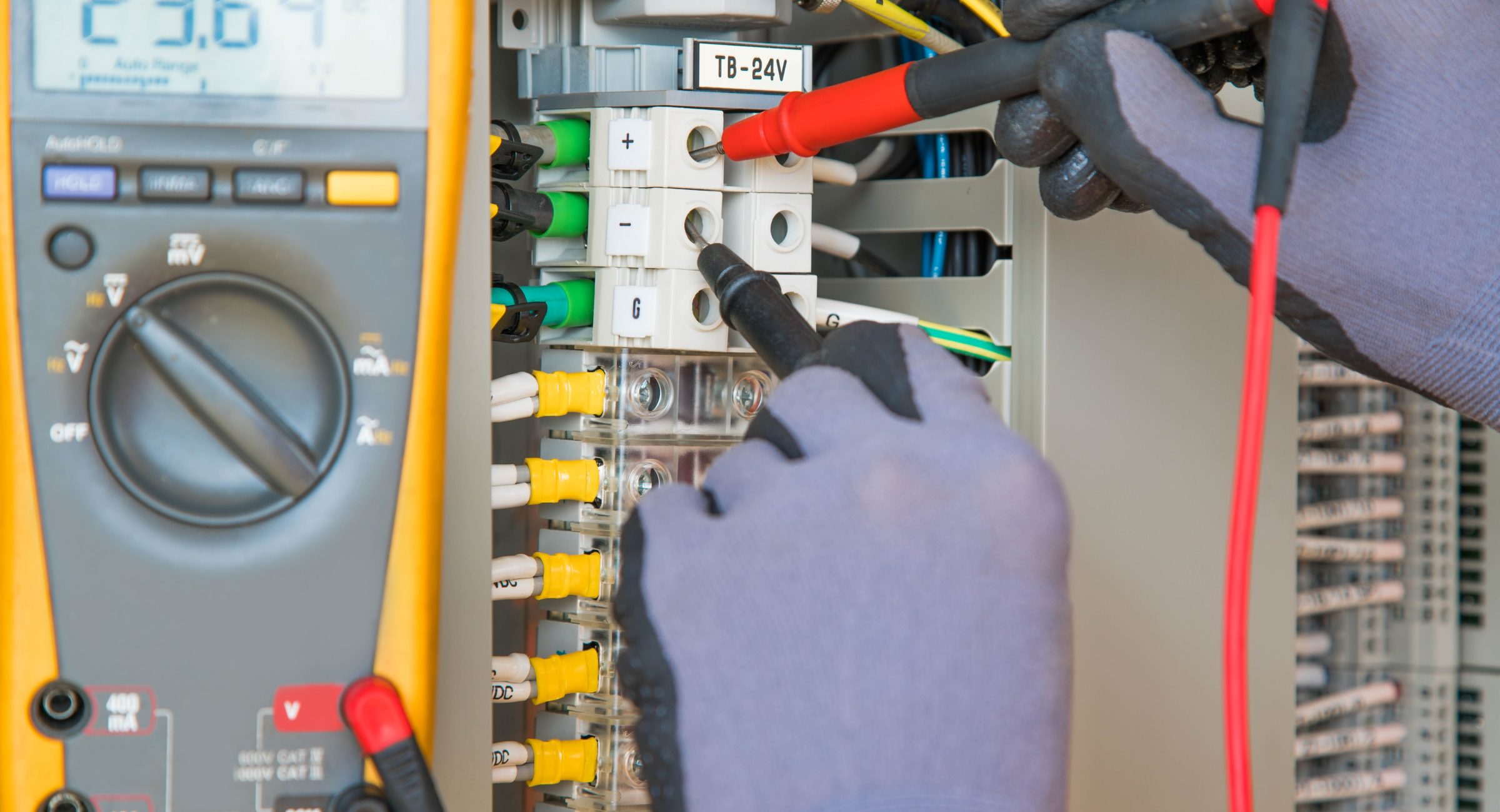

A programmable logic controller (PLC) is at the heart of most automation control systems; in order to ensure optimal quality, while managing cost and time considerations, we utilize validated software modules and design standard sets wherever possible. Quinea has developed and implemented PLC and more recently Process Automation Controller (PAC) applications in many industries using a host of different suppliers; these include, but are not limited to: Siemens, Allen Bradley, GE/Fanuc, Mitsubishi, Automation Direct, Omron, and Modicon. Our engineers are highly trained in system design, programming, and troubleshooting and we have the depth to handle everything from individual PLC machine control to large distributed control systems using Ladder, Function Block, and Structured Text.

Quinea is an expert in seamless migration from legacy PLC systems; aging installations leave the the owners exposed to failure, operational deficiencies from missing out on valuable process data, and many even lack knowledgeable OEM support. Quinea can bring your legacy systems up to optimal performance with up to date designs facilitating better control through faster communication, improved diagnostics, reduced power consumption, and easier integration into plant-wide systems. In addition, you will realize reduced downtime, reduced replacement cost, increased productivity, and improved product quality. If you have an AB PLC-2, PLC-3, PLC-5, Siemens 405, 505, S5, GE/Fanuc Series one/three/five/six PLCs still in operation we can replace it with a more robust solution

PLC Products

- Siemens SIMATIC Step 7 and TIA

- Allen-Bradley PLC/SLC and Logix 5000

- GE Proficy

We develop and deliver control systems for the North American market under IEC guidelines in accordance with EN 13849; we can also plan and execute system designs in accordance with NRTL requirements with approvals from UL, CSA, or TUV. System planning and circuit diagrams are similar to what you might find out of Europe, designed utilizing the EPLAN 5.70 or EPLAN Electric P8 CAD systems, both of which allow detailed sets of documents for subsequent project phases.

Documentation & TESTING

Whether you are trying to develop a new design package, or your organization is trying to conform to unfamiliar user requirements specifications, Quinea has experience with both the deliverable and receivable side of complex system specifications. We have worked in some of the most regulated locations and industries in the world; validating Life Sciences System or even conforming to NRC Codes, we can help you develop or comply with the challenging design deliverable packages and regulatory requirements.

Documentation is critical in order to understand system design and functionality; it is the first place engineering, maintenance, and operations staff reference when troubleshooting system issues. Improper documentation can result in long production outages and plant safety issues; accurate high quality documentation is also very important if changes and/or system upgrades are anticipated over the life of the product.

Where we really shine is the development of technical testing documentation; Quinea can help you establish criteria for Qualification and Acceptance Testing in order to ensure the system meets necessary design requirements, regulatory standards, and operational guidelines. Acceptance Testing is too often executed with the interests of success or hasty completion; we emphasize the importance of this testing as it will be the only macro evaluation of the complete operational environment. Our testing protocols are designed to identify deviations and examine related implications within the entirety of the affected subsystems; when properly executed and deployed, a properly documented system validation should be a functional part of your organizations engineering toolbox for the life of the system.

Over many years we have developed extensive testing protocols for a variety of processes; we can help you apply black box testing methods to custom developed processes or help you challenge white box testing procedures on existing processes.

FIELD SUPPORT

Quinea supports a number of OEMs with control system integration, commissioning, and testing at end-user locations all over North America. Our industrial engineering service offerings include interfacing factory lines with intelligent systems, such as recipe management systems, reporting and productivity monitoring systems, databases, PC and web applications, Supervisory Control and Data Acquisition (SCADA) systems, and MES (Manufacturing Execution Systems).

We work on many different software and hardware platforms and have several platform specific certifications.

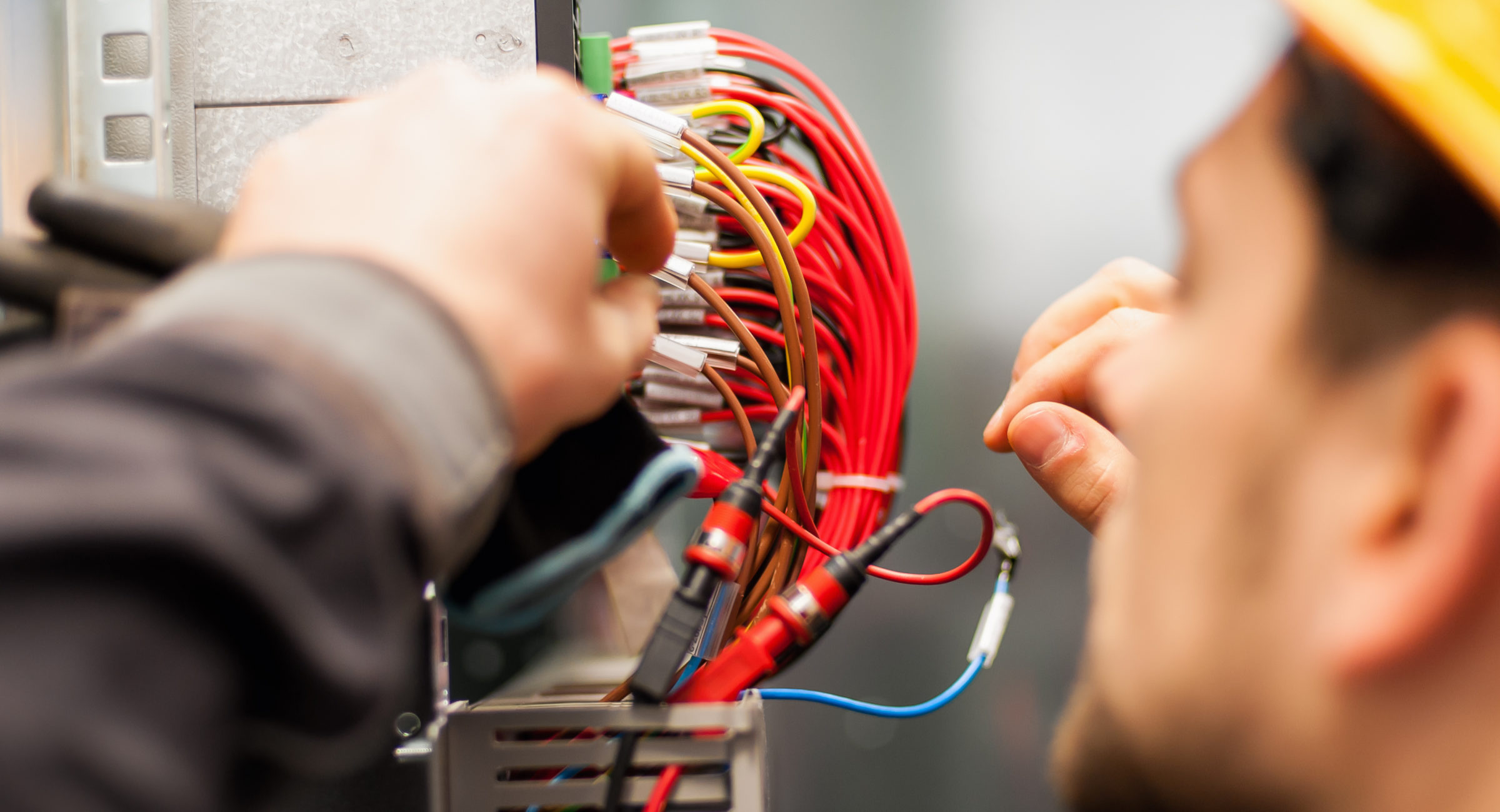

Quinea offers emergency breakdown support and repair services for a variety of control systems and components; including but not limited to PLCs, HMIs, Instrumentation, Drives, and Motors. What separates Quinea from most others is our experience with both electrical and mechanical systems; quite often, what might initially manifest as a control problem ends up being a peripheral issue. Whether it be an electrical, mechanical, or even process challenge; our team will resolve the issue and help your team implement a long term solution.

Our highly-trained engineers provide phone, remote access, and on-site support services 24/7; if your line is down, we understand the urgency, and will get you back in operation quickly.

We are reworking this content…please check back soon!

DYNAMIC. EFFICIENT. RELIABLE.

Passionate multi-disciplined engineers with real world experience in a wide range of industries…ready to help you plan, design, build, and integrate advanced processes and systems.